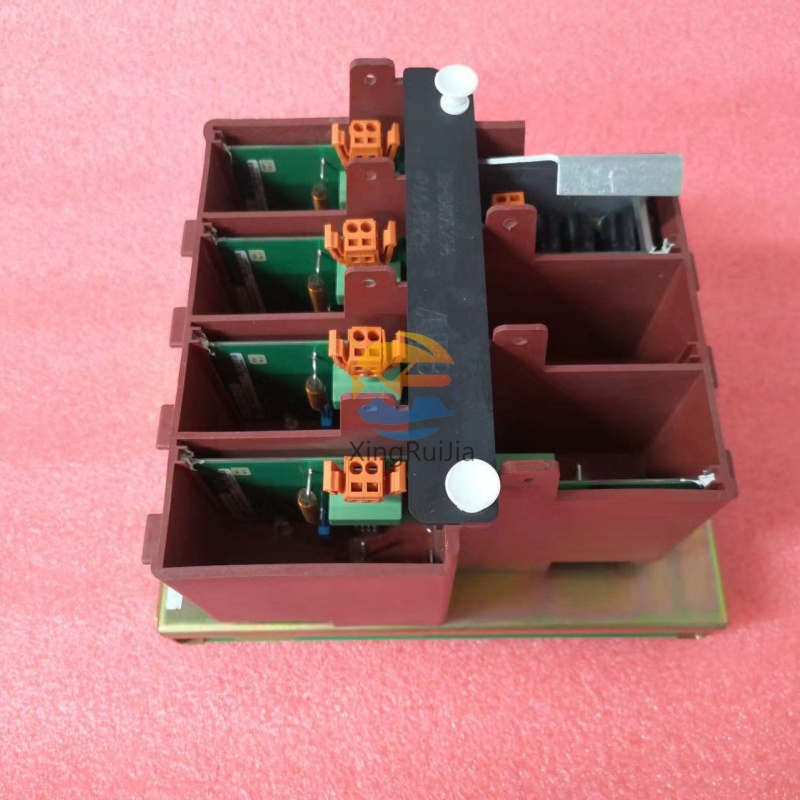

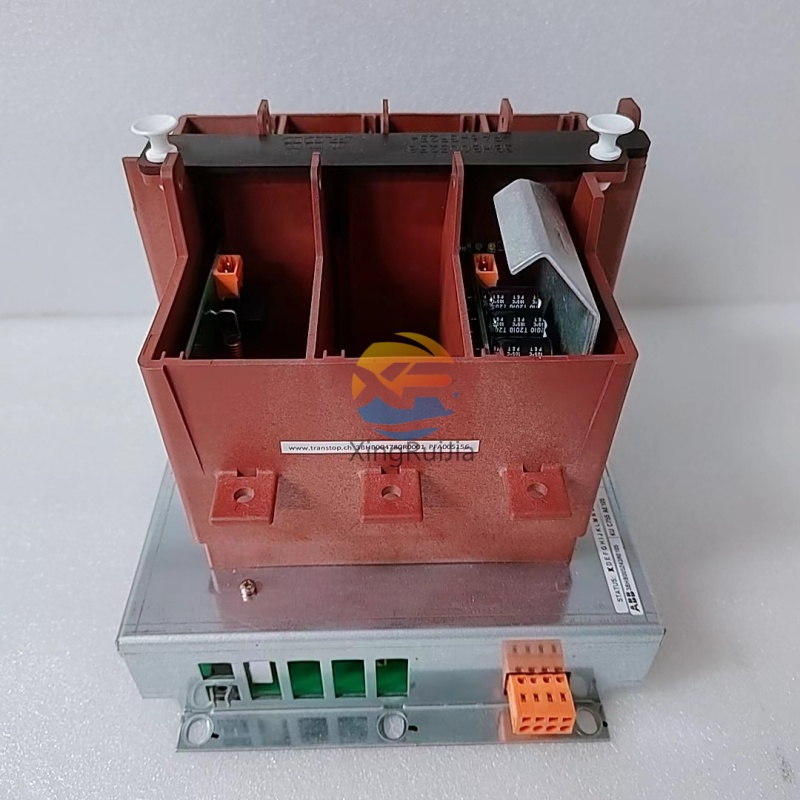

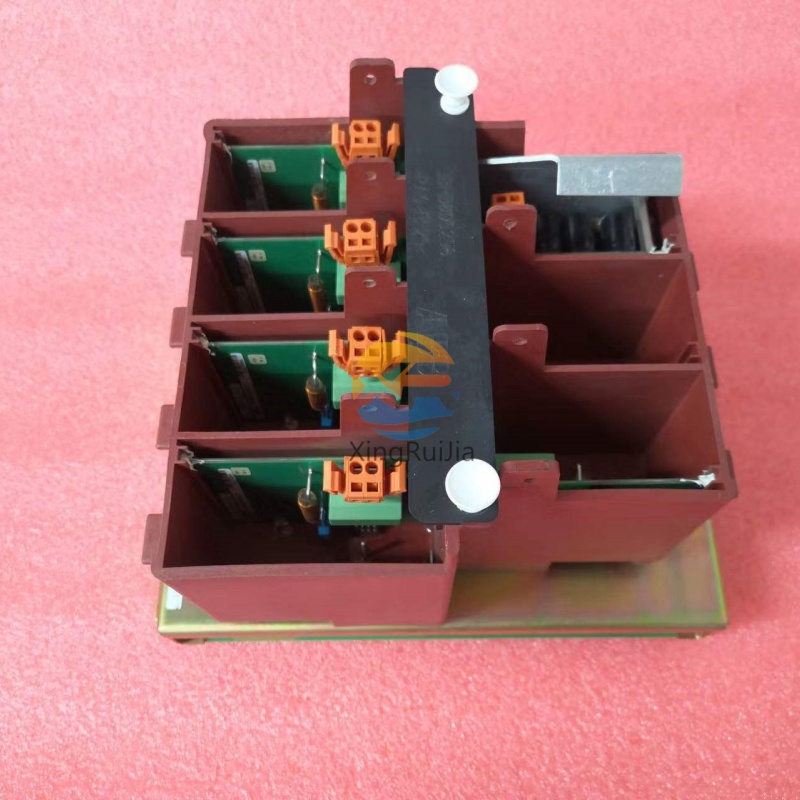

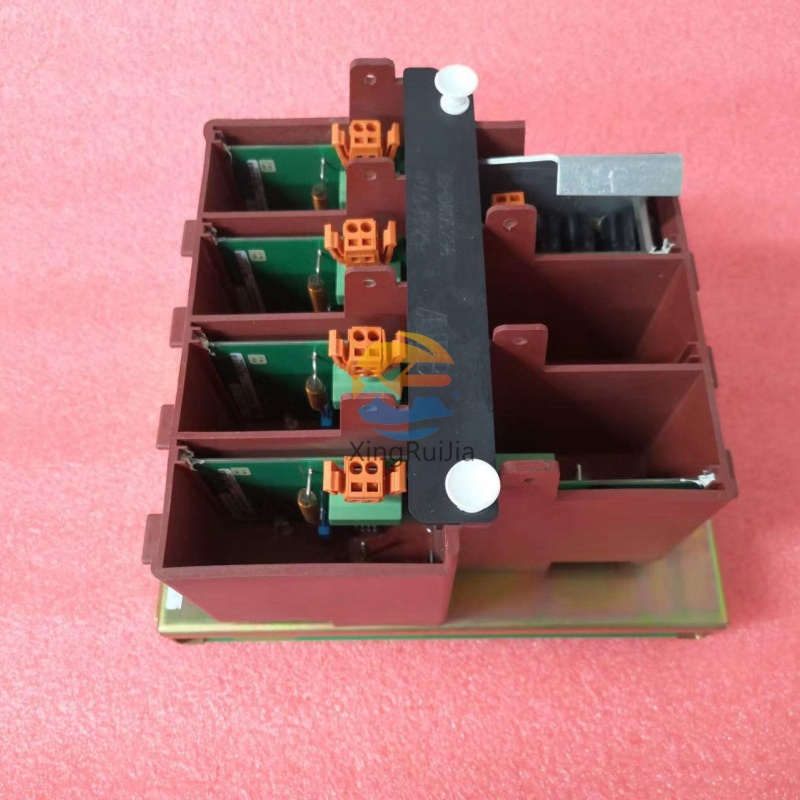

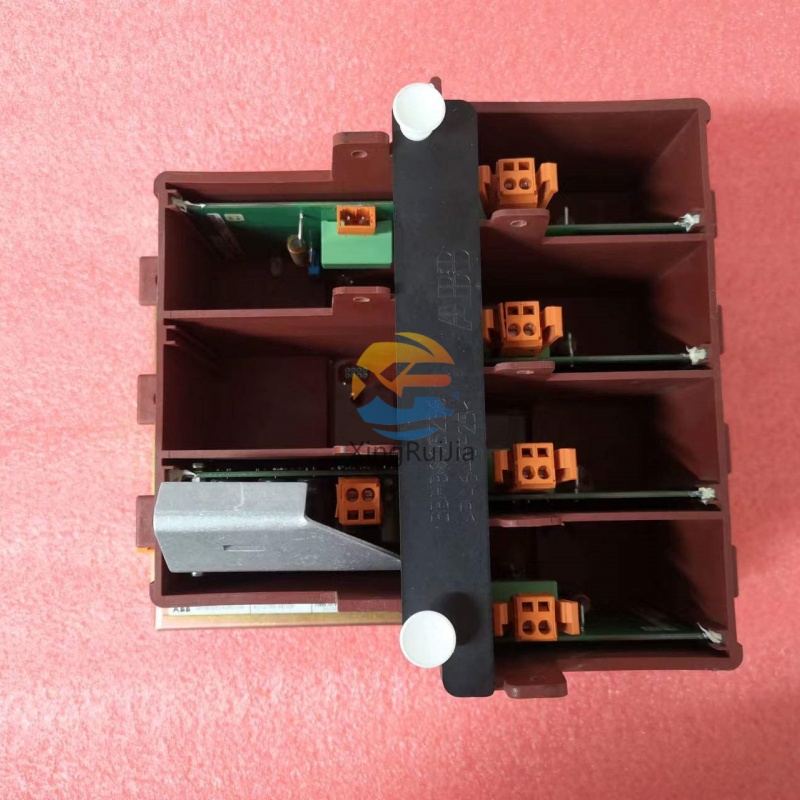

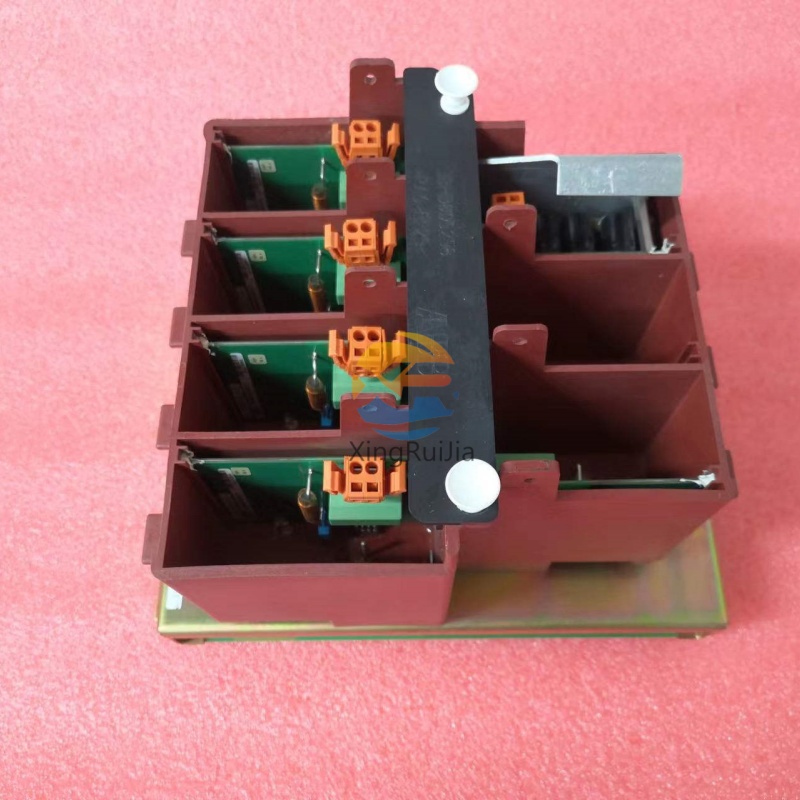

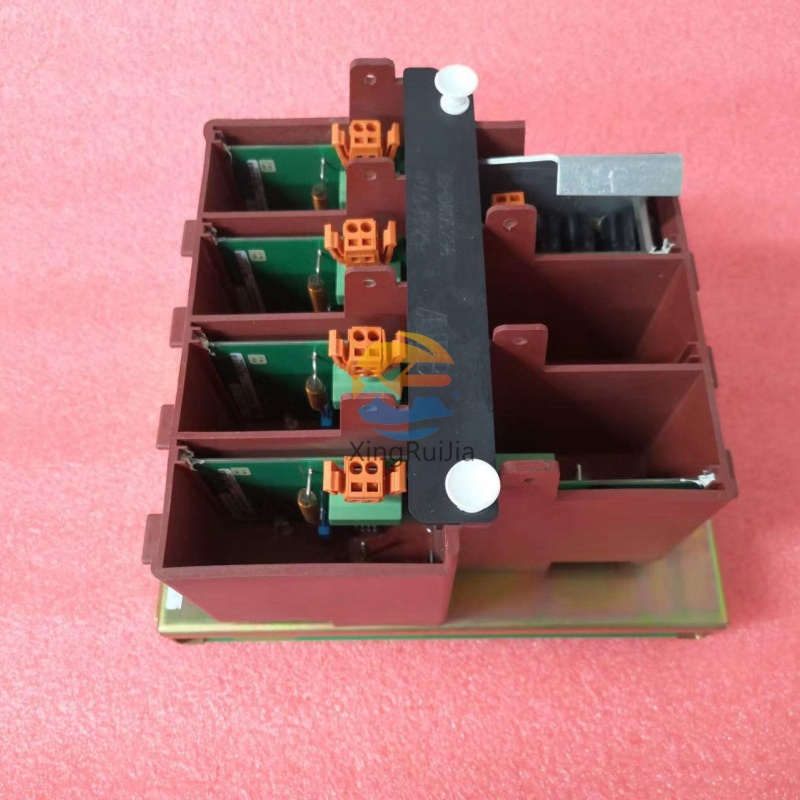

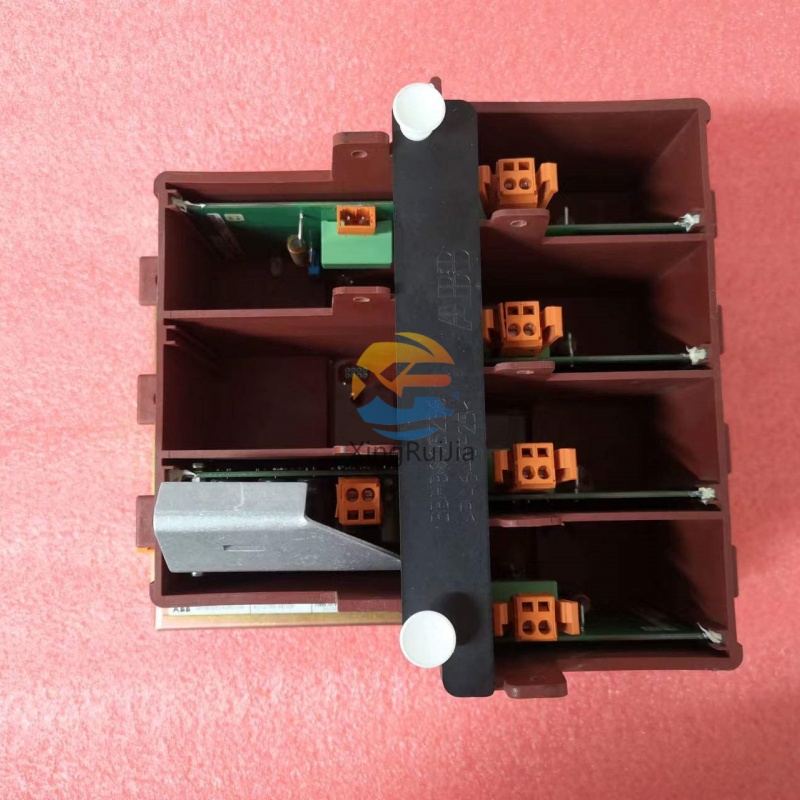

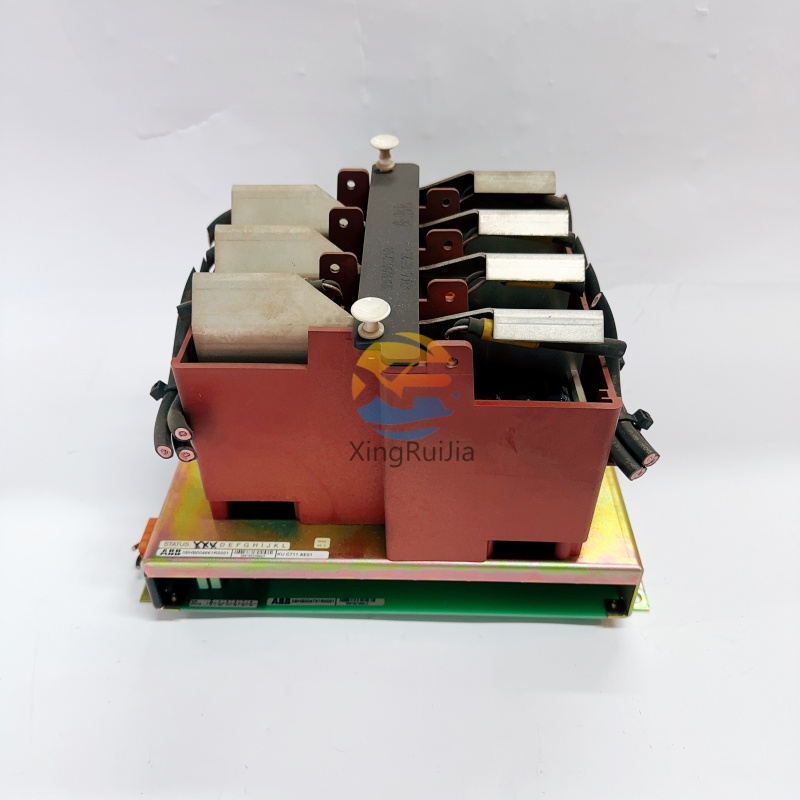

ABB KUC755AE106 3BHB005243R0106 Advant Controller 800xA | High-Integrity Turbine Control Solution

Introduction: Redefining Control in Critical Applications

In the demanding world of industrial automation, where process integrity, safety, and uptime are paramount, the control system forms the very heart of operations. For critical applications such as turbine control, power generation, and large process plants, the choice of controller is not just a technical decision but a strategic one. The ABB KUC755AE106 3BHB005243R0106 stands as a pinnacle of engineering in this domain.

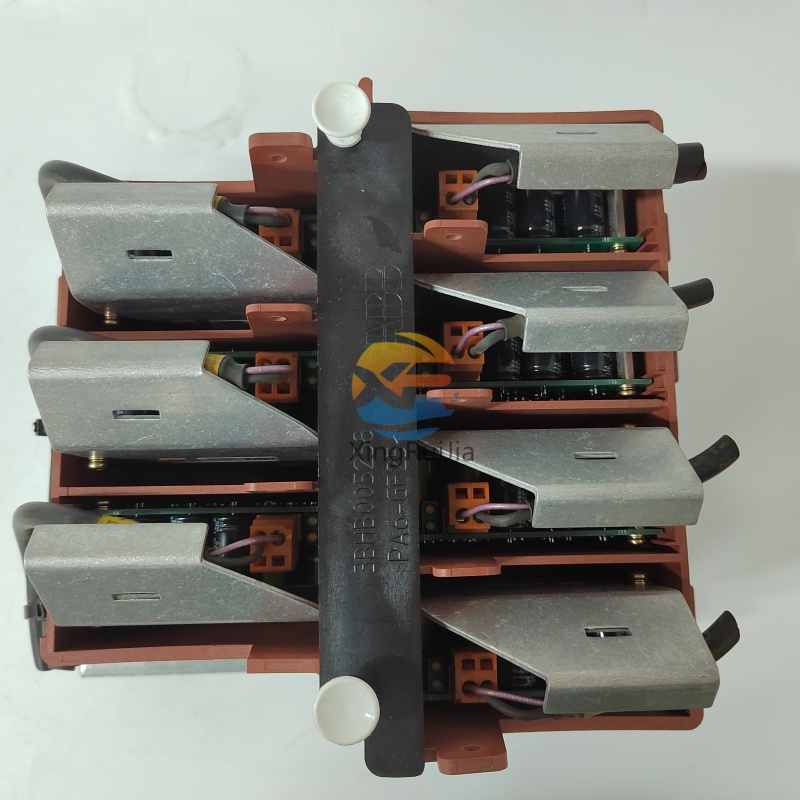

This product is a central processing unit (CPU) module from ABB's renowned Advant Controller 800xA series, specifically designed for high-reliability, redundant, and complex control tasks. As part of the larger ABB Ability™ System 800xA, the KUC755AE106 embodies a legacy of robustness and innovation, providing the computational power and deterministic performance required to manage and safeguard some of the most valuable industrial assets.

This comprehensive product detail page will delve deep into the specifications, functionalities, and unparalleled advantages of the KUC755AE106 module, providing engineers, procurement specialists, and plant managers with all the necessary information to understand its critical role in modern automation.

Product Overview and Identification

-

Manufacturer: ABB

-

Core Model: KUC755AE106

-

Full Order Code / Article Number: 3BHB005243R0106

-

Product Line: Advant Controller 800xA

-

Primary Function: High-Performance Process Control Module (CPU)

-

Key Application: Turbine Control, Compressor Control, Safety-Critical Process Automation.

The ABB KUC755AE106 is more than just a circuit board; it is the brain of a control loop. It executes control logic with extreme precision and speed, ensuring that processes operate within their designed parameters. Its architecture is built for environments where a system failure is not an option, featuring inherent support for redundancy and seamless integration with ABB's extensive I/O and networking modules.

Key Features and Unparalleled Benefits

The KUC755AE106 is packed with features that translate into direct benefits for your operation.

1. Exceptional Processing Power and Speed:

The module boasts a high-performance processor capable of handling vast amounts of I/O data and executing complex control algorithms with a fast and deterministic scan cycle. This ensures that control responses are swift and predictable, which is absolutely critical for turbine control where millisecond delays can have significant consequences.

2. Built-in High-Availability and Redundancy Support:

A standout feature of the KUC755AE106 is its design for fault-tolerant operations. It can be configured in a redundant (1:1) pair, where a primary and a backup module run in perfect synchrony. If the primary module fails, the backup takes over control without any interruption to the process—a bumpless transfer.

-

Benefit: Maximized plant availability, elimination of single points of failure, and guaranteed continuous operation, leading to significantly reduced downtime and production losses.

3. Seamless Integration with System 800xA:

As an integral component of the ABB Ability™ System 800xA, this controller operates within a unified automation and control environment. It shares data effortlessly with other aspects of the plant, including electrical systems, safety systems, and enterprise-level data analytics platforms.

-

Benefit: A single, integrated engineering and operational environment reduces complexity, lowers lifecycle costs, and provides operators with a holistic view of the plant for better decision-making.

4. Robust and Industrial-Grade Design:

Engineered for harsh industrial environments, the KUC755AE106 is built to withstand typical challenges like temperature fluctuations, electrical noise, and vibration. It meets rigorous industrial standards for EMI/RFI immunity.

-

Benefit: High reliability and long service life, even in the most challenging conditions of power plants, oil & gas facilities, and heavy industrial sites.

5. Extensive Memory Capacity:

The module is equipped with ample user memory for storing large and sophisticated control programs, historical data logging, and complex sequence-of-operations.

6. Comprehensive Diagnostic Capabilities:

The module continuously monitors its own health and the status of the control network. It provides detailed diagnostic information that can be accessed locally or remotely, alerting maintenance personnel to potential issues before they lead to a failure.

Detailed Technical Specifications

For engineers and technical buyers, here is a detailed breakdown of the specifications for the ABB 3BHB005243R0106:

Primary Applications and Use Cases

The ABB KUC755AE106 is specifically engineered for mission-critical control applications. Its primary uses include:

-

Steam and Gas Turbine Control: Managing turbine startup, speed, load, and shutdown sequences with utmost precision and safety. It handles complex control loops for fuel, steam, and auxiliary systems.

-

Compressor Control: Regulating anti-surge and performance control for critical compressors in pipelines and process plants, protecting multi-million dollar equipment from damage.

-

Power Generation: Acting as a key controller in boilers, governors, and balance-of-plant systems within thermal, hydro, and combined-cycle power plants.

-

Complex Process Automation: Serving as the main controller for large-scale processes in industries like oil & gas, chemicals, and pulp & paper, where high availability and control integrity are required.

System Integration and Architecture

Understanding how the KUC755AE106 fits into a larger control system is crucial.

The module is typically housed in a rugged industrial rack, such as the ABB S800 I/O station. It communicates with distributed I/O modules (digital input/output, analog input/output, specialty modules) via a high-speed fieldbus, primarily the MasterBus 300 (MB300). This creates a distributed control architecture where the CPU can be located in a control room while I/O modules are placed close to the field devices, reducing wiring costs and improving signal integrity.

In a redundant configuration, two KUC755AE106 modules are installed in a special redundant base unit. They are connected via a high-speed synchronization link, constantly mirroring the application program and process data. This entire system is then configured and programmed using ABB's powerful engineering tool, Control Builder M, which provides a graphical environment for logic design, configuration, and troubleshooting.

Why Choose the ABB KUC755AE106? The Competitive Advantage

Investing in the KUC755AE106 is an investment in plant performance and longevity.

-

Proven Reliability: With a legacy spanning decades in thousands of installations worldwide, the Advant Controller platform has a track record of unparalleled reliability.

-

Future-Proof Platform: Being part of the System 800xA, it offers a migration path for older ABB systems (e.g., Advant OCS) and ensures long-term support and component availability.

-

Comprehensive Support: ABB's global network of support engineers and service professionals provides everything from initial commissioning to lifecycle maintenance and spare parts.

-

Reduced Total Cost of Ownership (TCO): While the initial investment might be higher than a standard PLC, the dramatic reduction in unplanned downtime, the ease of maintenance, and the extended lifecycle result in a significantly lower TCO.

Sourcing, Compatibility, and Lifecycle Support

The ABB KUC755AE106 3BHB005243R0106 is a critical spare part for many existing plants. When sourcing this module, it is essential to partner with reliable suppliers who can guarantee:

-

Authenticity: The product is a genuine, new or refurbished-by-ABB unit, not a counterfeit.

-

Condition: Clear information on whether the unit is new, refurbished, or used.

-

Warranty: A supplier-provided warranty is a strong indicator of product quality.

-

Compatibility: Ensure compatibility with existing system racks, power supplies, and I/O modules (e.g., other S800 modules).

ABB offers extensive lifecycle support for its products, and the KUC755AE106, while part of a mature product line, is still actively supported with repair services and technical documentation.

Frequently Asked Questions (FAQ)

Q1: Is the KUC755AE106 still manufactured by ABB?

A: While it may be in a mature or selective production phase, ABB continues to provide full lifecycle support, including repair services and guaranteed spare part availability for many years. It is crucial to check with ABB or an authorized distributor for the current status.

Q2: Can I use the KUC755AE106 as a standalone controller?

A: No, it is a module that must be installed in a compatible ABB S800 I/O station with a suitable power supply and connected I/O modules to form a complete control system.

Q3: What is the difference between KUC755AE106 and other KUC7xx models?

A: Different suffixes and model numbers often indicate variations in processing speed, memory capacity, or specific firmware features for targeted applications. The KUC755AE106 is a high-performance model tailored for critical tasks like turbine control.

Q4: How do I program the KUC755AE106?

A: It is programmed using ABB's Control Builder M engineering software, which uses standardized programming languages like Function Block Diagram (FBD) and Structured Text (ST) per the IEC 61131-3 standard.

Q5: My plant has an older ABB MOD 300 or Advant OCS system. Is the KUC755AE106 compatible?

A: The System 800xA, including the KUC755AE106, is designed as a strategic migration path for these older systems. While not a direct, drop-in replacement, ABB provides well-defined migration tools and services to transition your application logic and configuration.

Conclusion: The Benchmark for Critical Control

The ABB KUC755AE106 3BHB005243R0106 is not merely a product; it is a testament to ABB's commitment to engineering excellence. It represents a robust, reliable, and high-performance solution for industries where control failure is not an option. Its capabilities in turbine control, compressor protection, and complex process automation make it an indispensable asset for ensuring safety, maximizing availability, and optimizing performance.

For those responsible for maintaining, upgrading, or building a world-class automation system, specifying the KUC755AE106 is a decision that guarantees peace of mind and operational excellence for years to come.

Call to Action:

Ready to secure your critical control infrastructure? Contact us today for a competitive quote, technical datasheets, and expert consultation on the ABB KUC755AE106. We can assist with sourcing genuine modules, system integration advice, and lifecycle support to keep your operations running smoothly.

Sweden

Sweden

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Sweden

Sweden