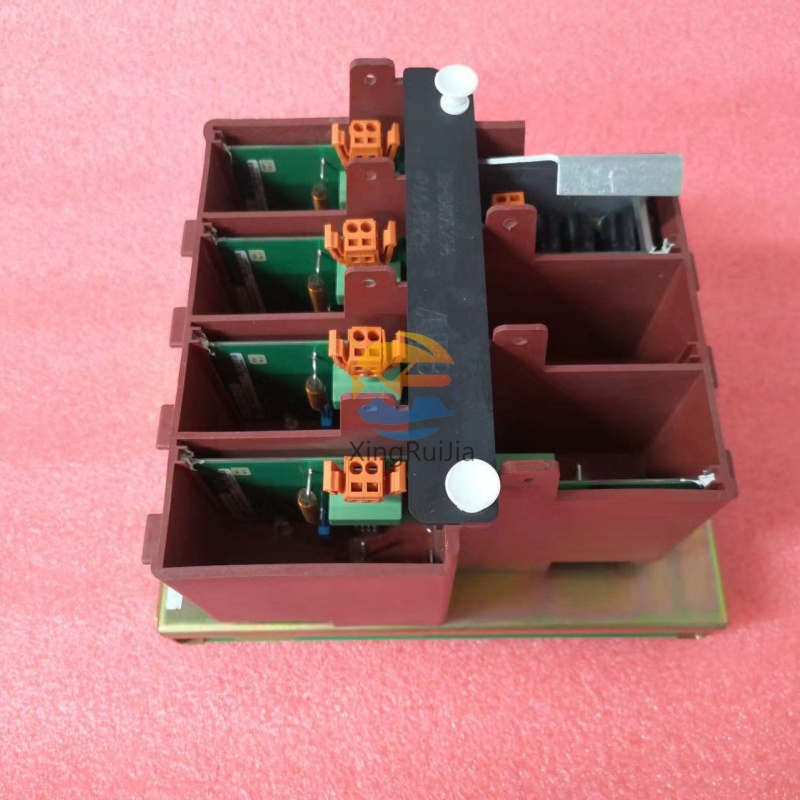

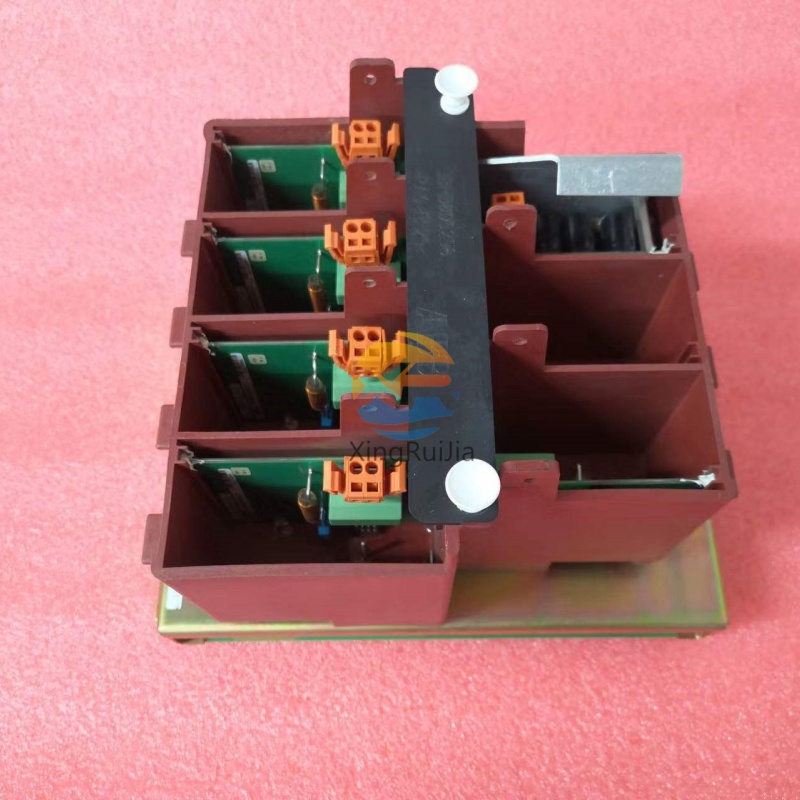

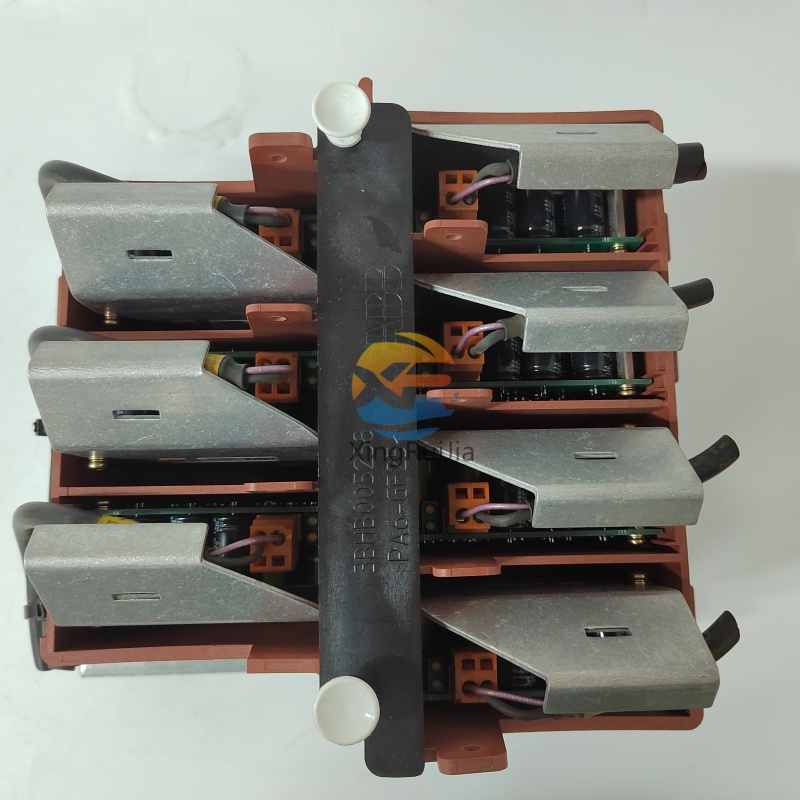

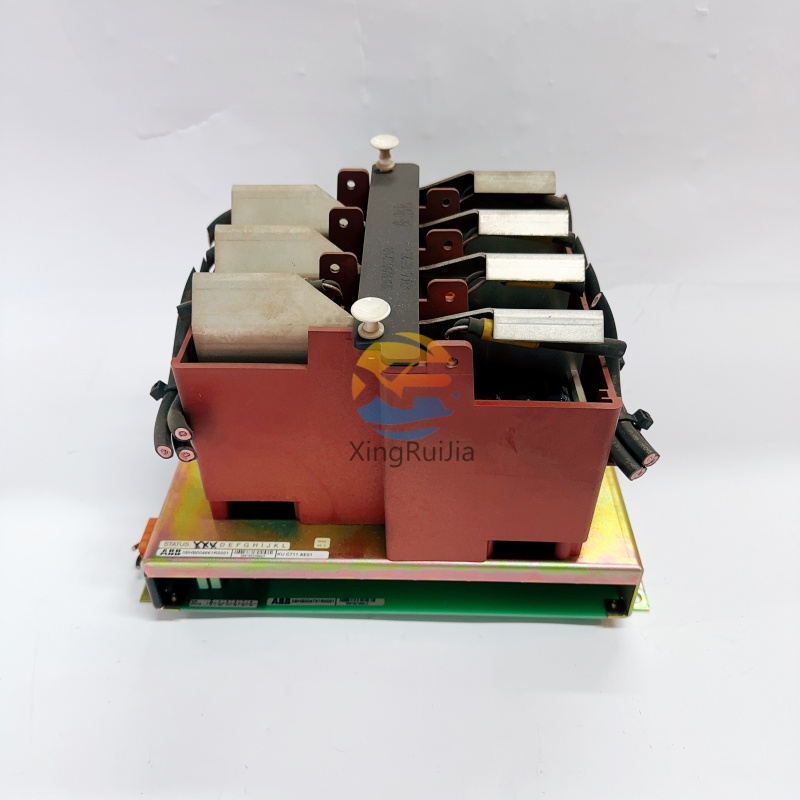

Product Overview: The Computational Heart of a Legacy Giant

The ABB KUC321AE HIEE300698R1 is not merely a component; it is the central processing unit (CPU) of the Master Piece Controller (MPC) family, a cornerstone of the legendary ABB Advant OCS (Open Control System) and its predecessor, the MOD 300 system. This powerful and reliable automation controller was engineered to manage complex, critical processes in some of the world's most demanding industrial environments.

Functioning as the "brain" of the control loop, the KUC321AE MPC is responsible for executing the control logic, managing sequential operations, handling complex calculations, and coordinating data flow between I/O subsystems and higher-level supervisory systems. Its design reflects an era where robustness, deterministic performance, and long-term stability were paramount. Even today, thousands of these controllers remain in active service, powering essential infrastructure in power generation, oil & gas, and chemical processing plants globally. This page serves as the definitive technical resource for engineers and technicians working with this pivotal piece of automation history.

Detailed Technical Specifications

A thorough understanding of the KUC321AE's specifications is crucial for system design, troubleshooting, and replacement.

General Product Identification

Hardware & Physical Specifications

Communication & Networking Capabilities

The KUC321AE serves as a communication hub. It typically relies on companion communication modules in the same rack but coordinates all data traffic.

-

Internal Bus: MasterBus 200 - The high-speed, proprietary parallel bus used for communication within the MPC rack between the CPU, I/O processors, and other modules.

-

Plant Network Connectivity: To connect to the wider Advant OCS network (e.g., MasterBus 300) and higher-level systems, it requires dedicated communication modules in the MPC rack, such as:

-

KUC711AE: Ethernet TCP/IP interface module.

-

KUC755 / KUC756: Serial interface modules for terminals and printers.

-

This allows the MPC to communicate with Operator Stations, Engineering Stations, and other controllers.

Software & Programming

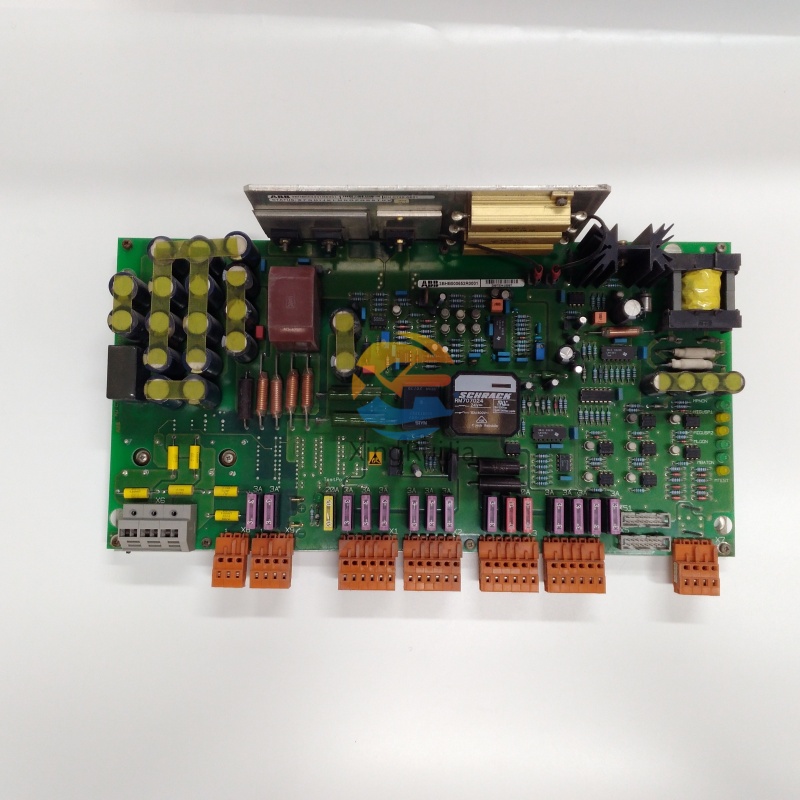

Diagnostic & Status Indicators

The front panel of the KUC321AE features a comprehensive array of LEDs for at-a-glance health and status monitoring:

-

PWR (Power): Indicates that the module is receiving correct power from the backplane.

-

RUN: A steady or flashing green light indicates the controller is in normal RUN mode, executing the control program.

-

ERR / FAIL: A red light indicates a critical hardware fault or a major system error that has halted the controller.

-

COM / BUS: Indicates activity and status on the internal MasterBus 200.

Key Features and Operational Benefits

The KUC321AE MPC was designed to deliver unparalleled performance and reliability.

-

Deterministic, High-Speed Performance: The core strength of the KUC321AE is its deterministic scan cycle. It guarantees that control logic is executed within a predictable and consistent time frame, which is absolutely critical for closed-loop control, safety interlocks, and high-speed sequencing in complex processes.

-

Exceptional Processing Power for its Era: For its generation, the KUC321AE offered significant computational power and memory capacity. This enabled it to handle not just simple logic but also advanced process control algorithms, complex batch management, and extensive data handling, consolidating control that might otherwise require multiple smaller PLCs.

-

Robust and Fault-Tolerant Architecture: The entire MPC platform, centered on the KUC321AE, was built for high availability. Key features included:

-

Hardware Redundancy: Support for fully redundant CPU configurations (KUC321AE could be paired with a standby unit) and redundant power supplies, ensuring continuous operation even in the event of a hardware failure.

-

Robust Design: Industrial-grade components and construction ensured longevity in harsh environments with electrical noise, vibration, and wide temperature swings.

-

Seamless Integration within Advant OCS: The controller is a native citizen of the ABB ecosystem. It integrates flawlessly with ABB's S800 I/O system (via AF 100 fieldbus) and other ABB components, providing a unified, vendor-optimized solution that reduces integration headaches and compatibility risks.

-

Comprehensive Diagnostics and Maintenance Support: The module provides detailed self-diagnostics. Faults are reported via the LED indicators and, more importantly, are logged in the system's event history with precise timestamps. This allows maintenance teams to quickly identify and rectify issues, minimizing mean-time-to-repair (MTTR).

Primary Applications and Industries Served

The ABB Master Piece Controller 200 family, with the KUC321AE at its core, was deployed in mission-critical applications across heavy industries.

-

Power Generation: The controller is found governing turbine control systems, boiler control (BMS, FSSS), reactor control in nuclear plants, and balance-of-plant operations (water treatment, compressor control).

-

Oil & Gas: Used for controlling offshore platform systems, safety instrumented systems (SIS), pipeline compressor stations, and complex refining processes like catalytic cracking and distillation.

-

Chemical & Petrochemical: Manages continuous and batch processes, controlling reactors, distillation columns, and complex separation units where precise temperature, pressure, and flow control are vital for safety and product quality.

-

Pulp & Paper: Controls the entire paper machine from the wet end to the dry end, managing stock preparation, coating, and reel finishing.

-

Metals & Mining: Automates rolling mills, furnace controls, and material handling systems.

System Integration and Architecture

Compatible Systems and Components

The KUC321AE HIEE300698R1 is the central component of:

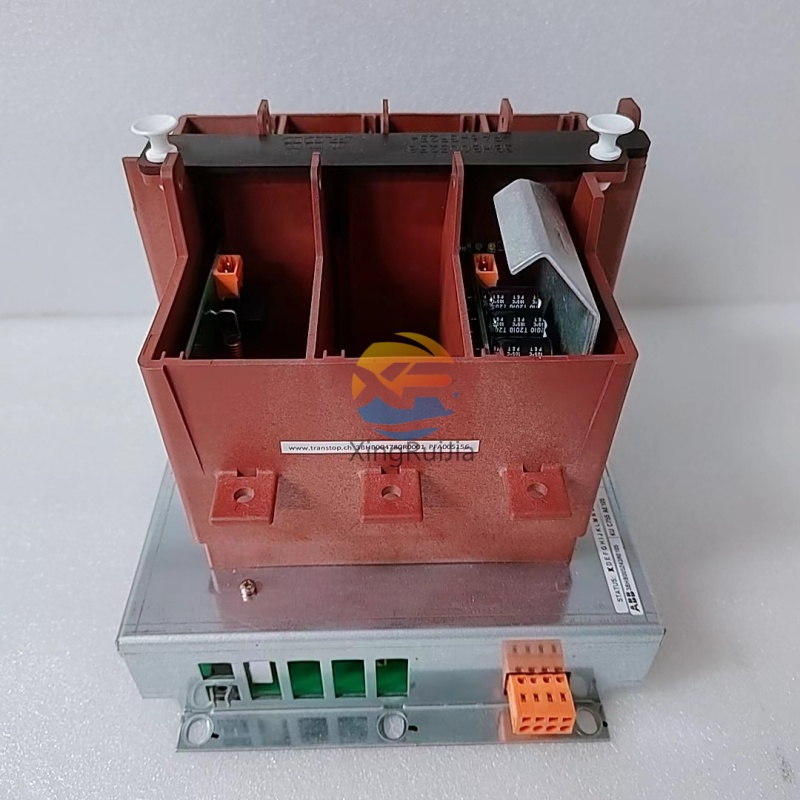

Installation and Replacement Procedure

Critical Safety Warning: Always follow site safety procedures. De-energize the entire MPC rack before handling any modules. Use an ESD (Electrostatic Discharge) wrist strap to prevent damage to sensitive electronics.

-

Preparation:

-

Ensure you have a complete and verified backup of the controller's program and configuration from the engineering station.

-

Document all cable connections to the rack.

-

Power down the MPC rack and all associated systems.

-

Module Removal:

-

Locate the KUC321AE module in its designated slot (usually slot 1 or a specific CPU slot).

-

Release the locking lever or screws securing the module.

-

Firmly and evenly pull the module straight out from the backplane connector.

-

Module Installation:

-

Align the new or replacement KUC321AE HIEE300698R1 module with the guide rails of the correct slot.

-

Slide the module in gently but firmly until it is fully seated in the backplane connector.

-

Secure the module with the locking lever or screws.

-

Power-Up and Verification:

-

Restore power to the MPC rack.

-

Observe the LED status indicators on the KUC321AE. The PWR LED should light, followed by the RUN LED flashing or becoming steady, indicating a successful boot and program execution.

-

Connect the engineering station and verify that the controller is recognized and communicating correctly. Check the system event log for any errors.

Comprehensive Troubleshooting and Diagnostic Guide

A structured approach is key to diagnosing issues with the KUC321AE.

LED Status Interpretation

Common Fault Scenarios and Solutions

-

Scenario 1: Controller fails to start, ERR LED is red.

-

Cause: Corrupted application memory; faulty battery leading to memory loss; hardware failure.

-

Solution: Connect with the engineering station and attempt to download a known-good program backup. If the download fails or the error persists, the CPU module is likely faulty and requires replacement.

-

Scenario 2: Intermittent communication loss with I/O or network.

-

Cause: A failing communication module (e.g., KUC711AE) in the rack; loose backplane connections; or a problem with the KUC321AE's bus controller.

-

Solution: Reseat all modules in the rack. Check the status of the communication modules. If the problem persists, try replacing the communication module first, then suspect the CPU.

-

Scenario 3: Controller loses time and program after a power cycle.

-

Cause: The battery backup for the memory and real-time clock is depleted or faulty.

-

Solution: Replace the battery module immediately. This is a scheduled maintenance item. After replacement, power up the controller and download the application program again. Reset the real-time clock.

Why Source an Authentic ABB KUC321AE HIEE300698R1?

The CPU is the most critical component in your control system. Compromising on its quality is not an option.

-

Guaranteed Performance and Compatibility: Only a genuine or certified refurbished ABB module can guarantee it will execute the control program exactly as designed and communicate flawlessly with the other modules in the MPC rack.

-

System Stability and Safety: A counterfeit or untested CPU can introduce unpredictable behavior, logic errors, and communication crashes, potentially leading to process shutdowns, safety risks, or equipment damage.

-

Long-Term Reliability and Support: Authentic ABB components are built to last. Sourcing from a reputable supplier ensures you receive a module that has been tested to perform for the remainder of its service life, with technical support available if needed.

-

Firmware and Software Compatibility: The firmware on a genuine KUC321AE is guaranteed to be compatible with the ABB Control Builder software, preventing project download and configuration issues.

Frequently Asked Questions (FAQ)

Q1: What is the difference between the MPC 200 (KUC321AE) and other ABB controllers like the AC 31?

A1: The MPC 200 (KUC321AE) is part of the earlier MOD 300 / early Advant OCS architecture and uses MasterBus 200 internally. The AC 31 controller is from a later generation of the Advant OCS and uses MasterBus 300 as its internal bus. They are not directly compatible and are programmed and configured with different, though related, software tools.

Q2: Can I still get technical support and documentation for this legacy controller?

A2: Yes. While it is a legacy product, ABB and specialized third-party support providers maintain documentation and expertise. The user manuals, data sheets, and configuration guides for the MPC 200 family are still accessible.

Q3: Is the program memory stored on the KUC321AE module itself?

A3: Yes, the application program is stored in the battery-backed RAM or non-volatile memory on the CPU module. This is why a failed battery results in program loss upon power cycle.

Q4: What is your warranty and testing process for this module?

A4: We understand the critical nature of a CPU. Every ABB KUC321AE HIEE300698R1 module we supply is sourced from reliable channels and undergoes a rigorous testing procedure in a live MPC test bench. We verify its power-up, memory functionality, communication with the backplane, and diagnostic capabilities. We provide a 12-month warranty and a certificate of test.

Q5: How do I confirm this is the exact replacement for my controller?

A5: The most reliable method is to check the part number on the label of the existing CPU module in your MPC rack. The label should clearly state KUC321AE and HIEE300698R1. You can also cross-reference your system's Bill of Materials (BOM) from the original ABB engineering project.

Conclusion: Your Trusted Source for Critical Control Components

The ABB KUC321AE HIEE300698R1 Master Piece Controller is a testament to an era of engineering built to last. Keeping these vital systems operational requires a partner who understands their criticality and possesses the technical expertise to support them.

We specialize in providing fully tested, guaranteed legacy ABB automation components. We don't just sell parts; we provide solutions that ensure the continuity and safety of your industrial processes.

Contact us today for a competitive quote, current stock availability, and expert technical consultation to ensure a seamless integration of your KUC321AE HIEE300698R1 controller.

Sweden

Sweden

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Sweden

Sweden