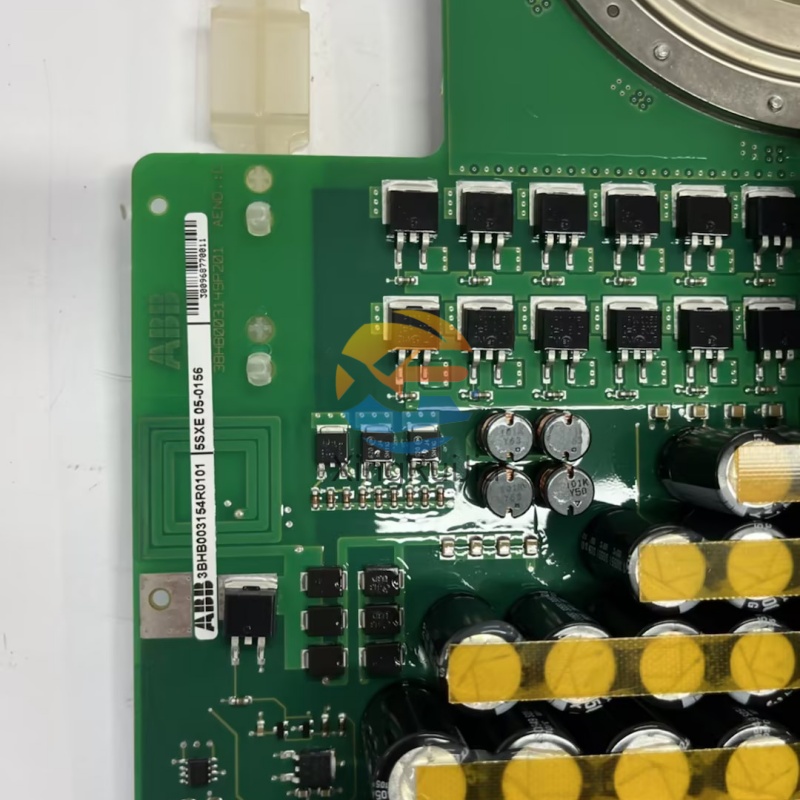

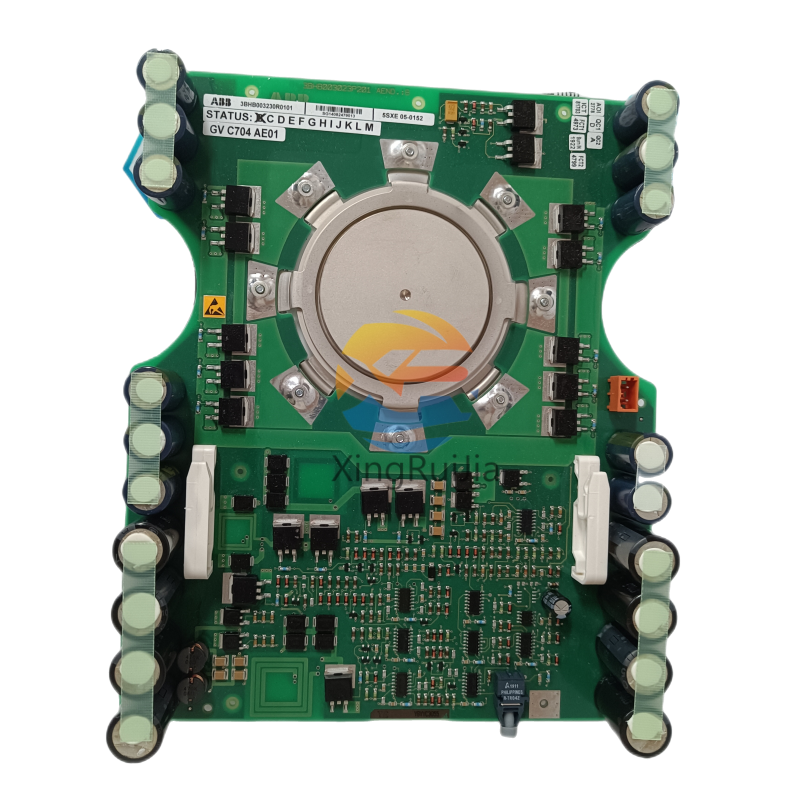

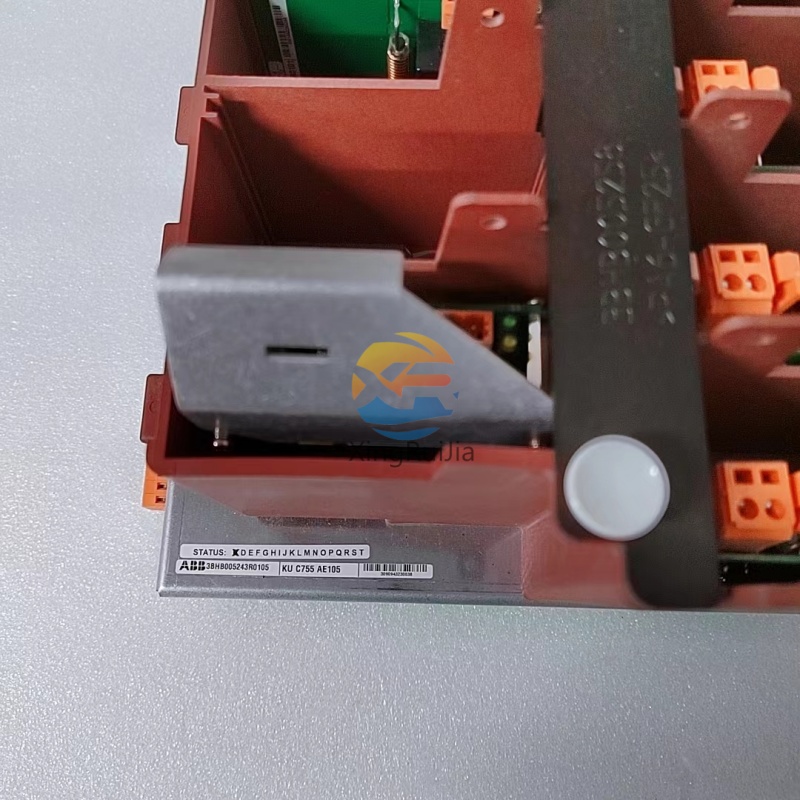

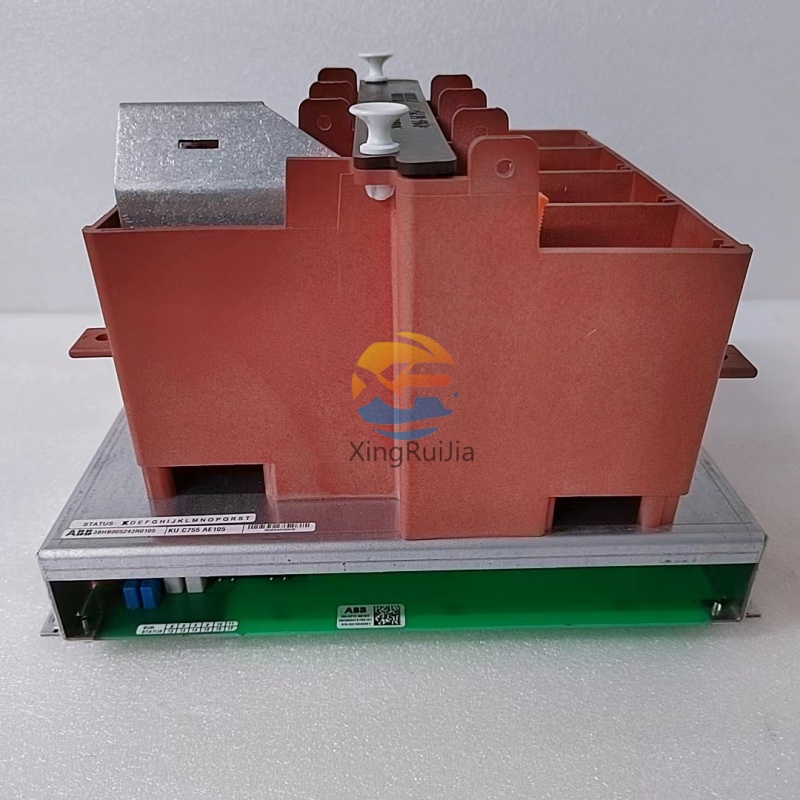

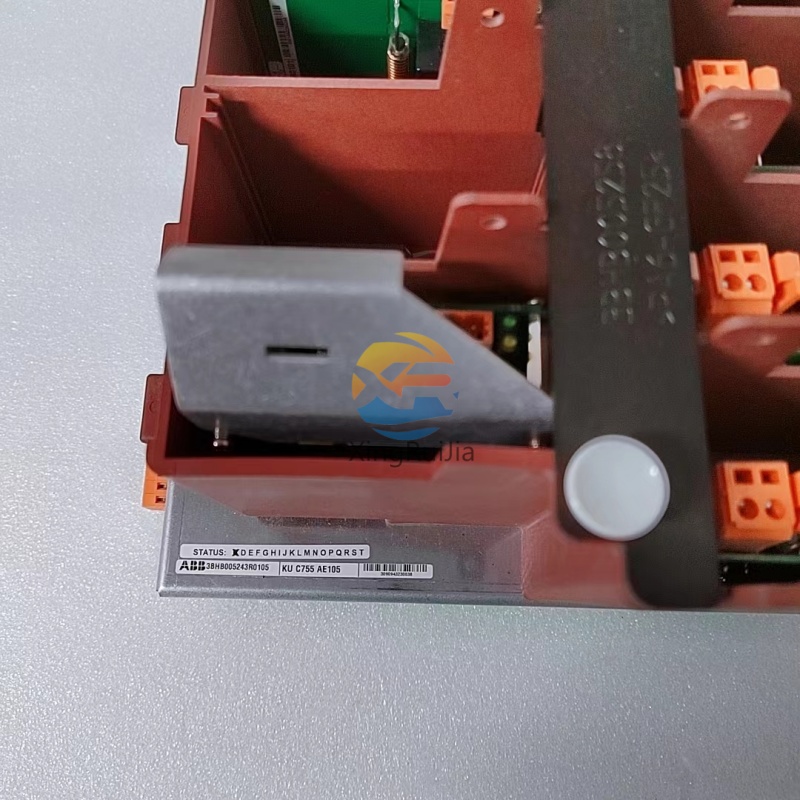

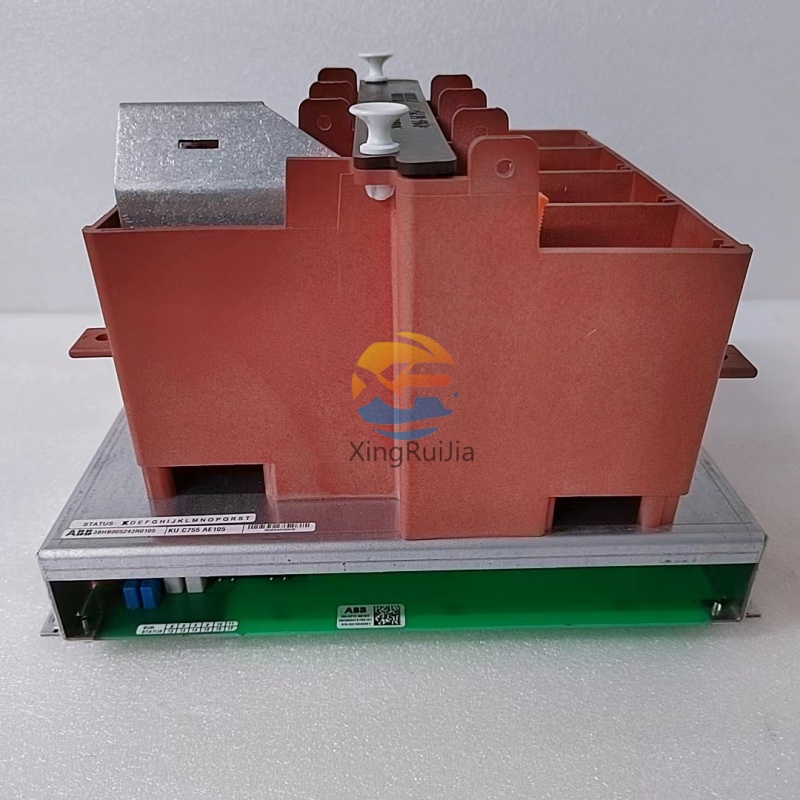

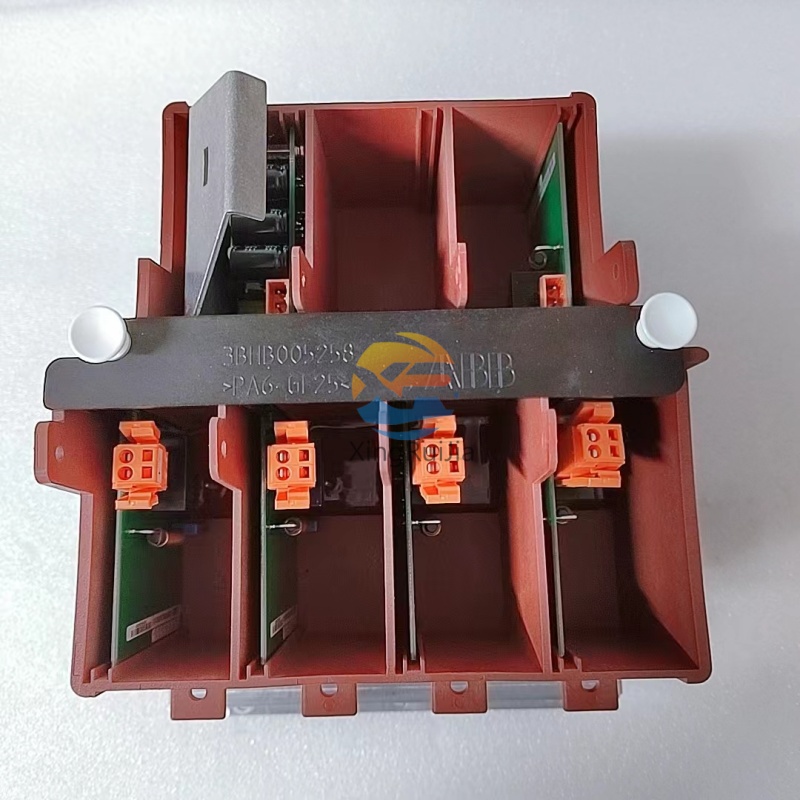

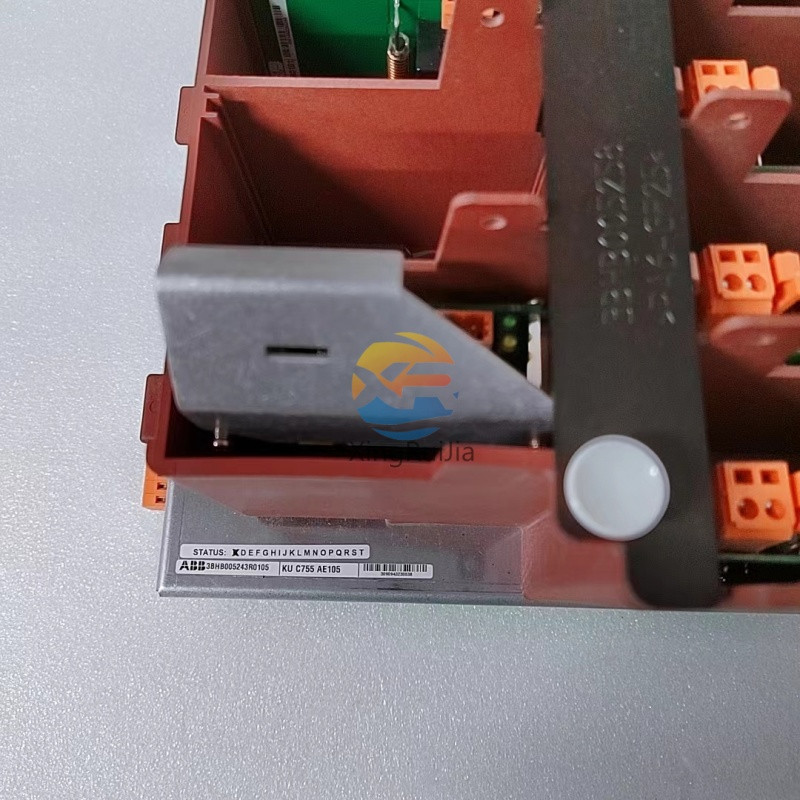

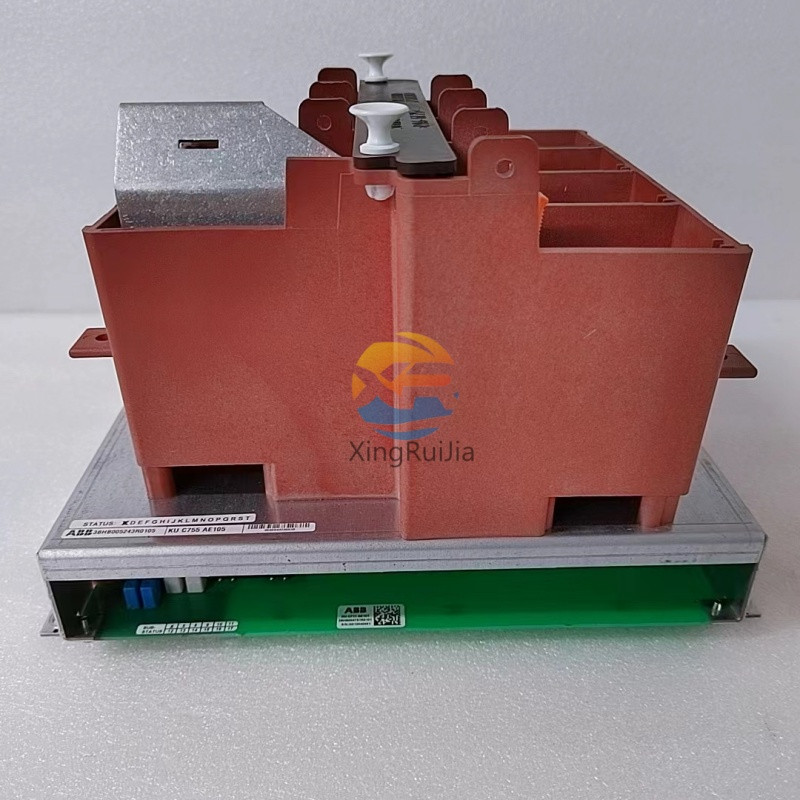

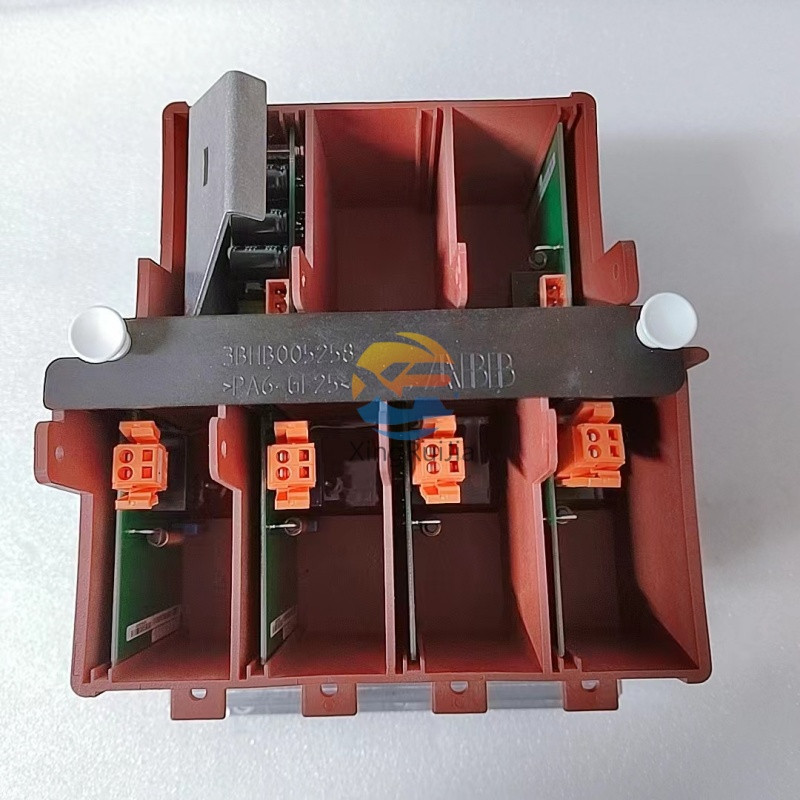

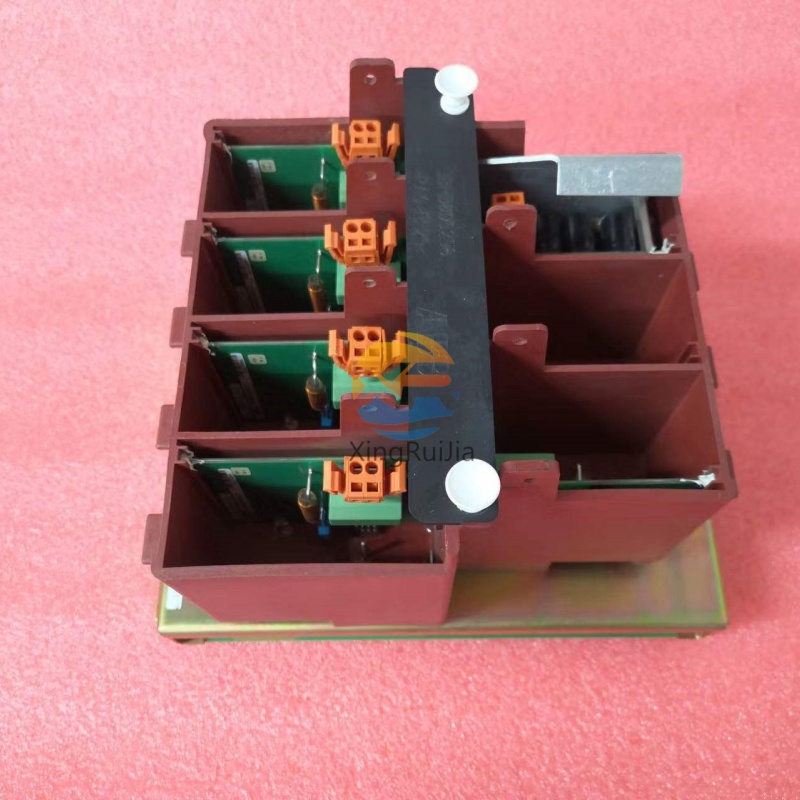

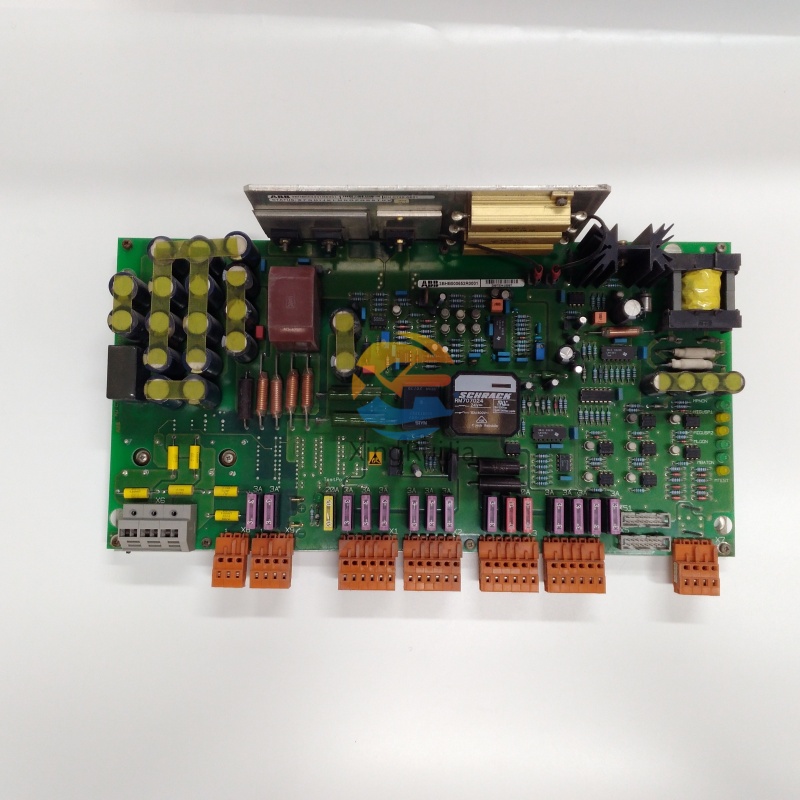

ABB KUC755AE105 3BHB005243R0105 | High-Integrity Turbine Control Module for Symphony Plus

The ABB KUC755AE105 3BHB005243R0105 is a high-performance, fault-tolerant controller module specifically engineered for the most demanding control and protection applications in industrial environments. As a core component of ABB's renowned Symphony™ Plus and Harmony/Innovation series of Distributed Control Systems (DCS), this module is the definitive choice for governing critical machinery such as gas turbines, steam turbines, and large compressors.

Where process safety, operational availability, and data integrity are non-negotiable, the KUC755AE105 excels. It is designed to execute complex control algorithms with millisecond precision, ensuring equipment operates within safe parameters, thus preventing catastrophic failures and maximizing asset lifespan. For control engineers, plant managers, and maintenance specialists in the power generation, oil & gas, and heavy industrial sectors, the KUC755 AE105 3BHB005243R0105 represents the gold standard in reliable, scalable, and secure automation control.

This comprehensive product overview delves into the technical specifications, architectural features, and application-specific benefits of this vital ABB component, providing the necessary information for system design, integration, and procurement.

Product Overview and Core Functionality

The KUC755AE105 is more than a simple PLC; it is a specialized controller within ABB's extensive ecosystem. Its primary role is to provide continuous, uninterrupted control and monitoring for high-speed rotating equipment.

-

Critical Process Control: It runs dedicated software for turbine control, managing functions like speed/acceleration control, temperature monitoring, sequencing (start-up/shutdown), and load balancing.

-

Integrated Safety & Protection: The module can execute safety instrumented functions (SIFs), acting as the primary logic solver for turbine protection systems to prevent overspeed, overtemperature, and lubrication failures.

-

Seamless DCS Integration: It natively integrates into the ABB Ability™ Symphony Plus DCS, allowing for centralized configuration, real-time monitoring, and historical data logging from a unified operator interface.

Key Features and Operational Advantages

The robustness of the KUC755AE105 is derived from a suite of advanced features designed for mission-critical applications:

-

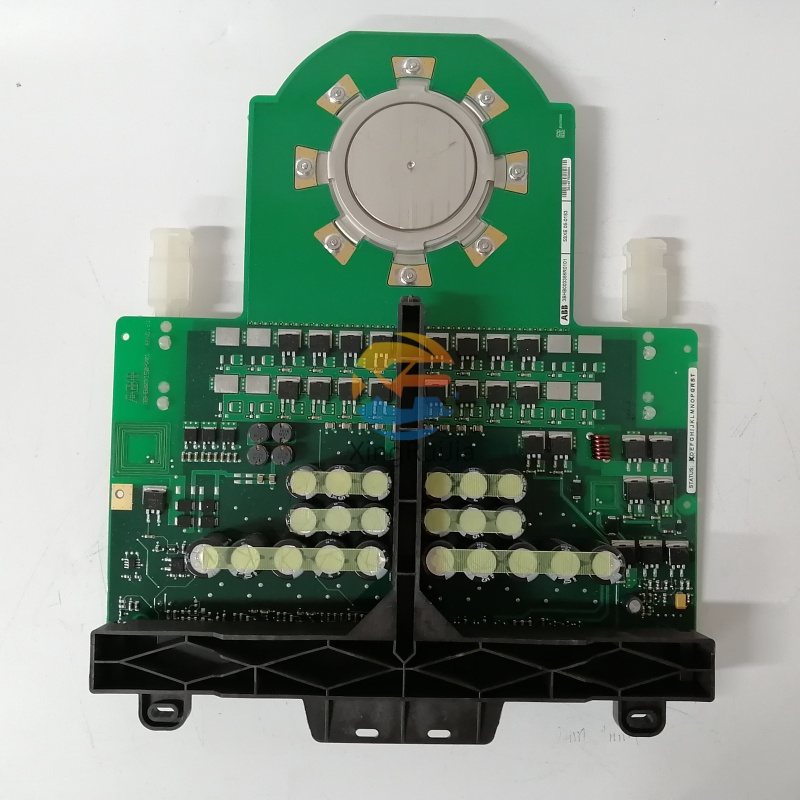

Triple Modular Redundant (TMR) Architecture Support: The module can be deployed in a TMR configuration, where three separate channels execute identical processes simultaneously. A hardware voting system masks any single channel failure, providing the highest possible level of fault tolerance and system availability, essential for critical turbine protection.

-

High-Speed Processing: Equipped with a powerful processor, it executes logic solvers and control loops with extreme speed and determinism, ensuring timely responses to fast-changing process conditions.

-

Robust Industrial Design: Built to withstand the harsh conditions of industrial and energy plants, including wide temperature ranges, significant humidity, and exposure to electromagnetic interference (EMI) and vibration.

-

Comprehensive Diagnostics: Features advanced self-diagnostic capabilities that monitor the health of the controller itself, its power supply, and communication links. Faults are reported immediately to the operator, enabling predictive maintenance and reducing mean-time-to-repair (MTTR).

-

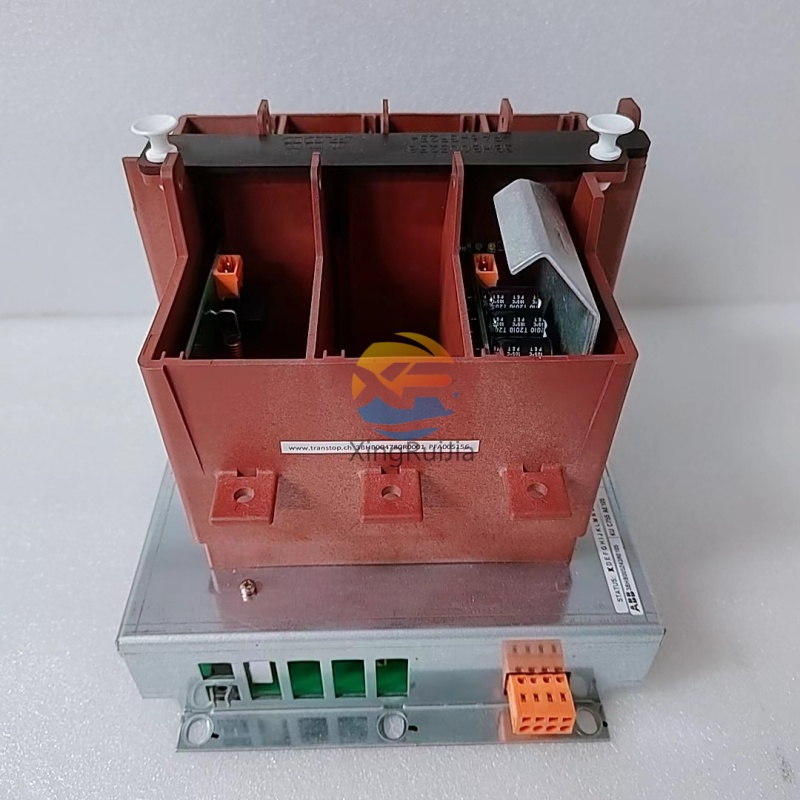

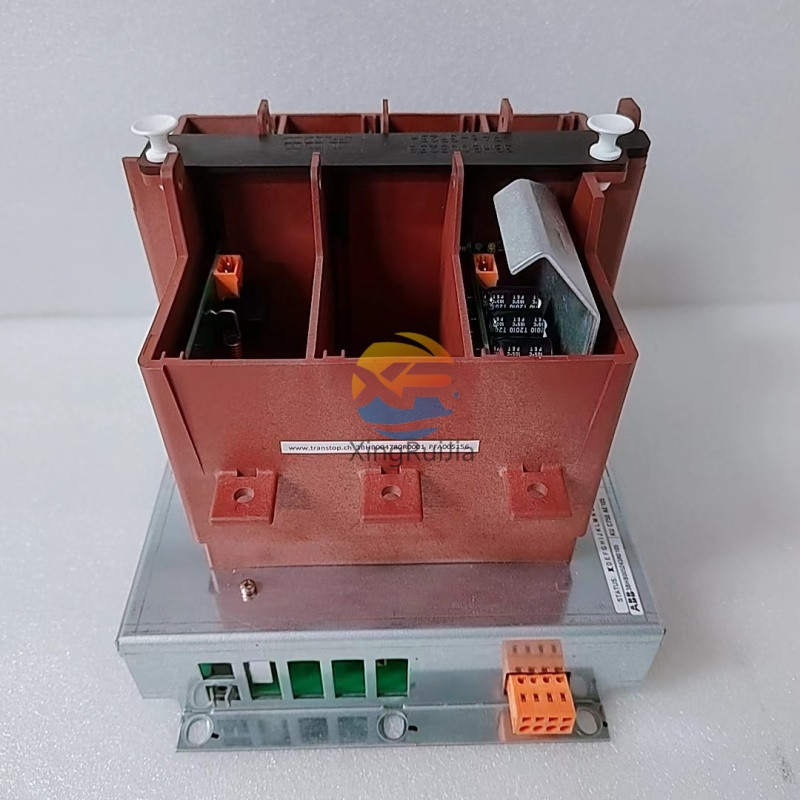

Flexible I/O Integration: Communicates seamlessly with ABB's S800 I/O family via a high-speed, deterministic network, enabling connection to a vast array of analog and digital field devices.

Detailed Technical Specifications

The following table provides a detailed breakdown of the technical specifications for the ABB KUC755AE105 3BHB005243R0105.

Typical Applications and Industries Served

The KUC755AE105 is deployed in industries where the reliable operation of turbines and compressors is directly linked to profitability and safety.

System Integration and Architecture

The KUC755AE105 is typically the central processing unit within a dedicated control node. A simplified integration overview:

-

Central Operator Station: Engineers monitor and supervise the turbine operation via the ABB Symphony Plus HMI.

-

Plant Network (e.g., Network 50/60): The data backbone connecting all system nodes.

-

ABB KUC755AE105 3BHB005243R0105 Controller: The brain of the turbine control system, executing the application code.

-

S800 I/O Network: A high-speed link to the I/O cards.

-

ABB S800 I/O Modules: Interface directly with field devices (sensors, transmitters, actuators).

Why Choose a Genuine ABB KUC755AE105 3BHB005243R0105?

Procuring a genuine ABB module is a critical investment in operational safety and reliability.

-

Assured Performance and Safety: Genuine modules are manufactured to exacting standards, ensuring control and safety functions perform as designed, protecting multi-million dollar assets.

-

Guaranteed Compatibility: Guaranteed to work flawlessly with the ABB Symphony Plus engineering tools (Control Builder M), S800 I/O, and network components.

-

Long-Term Reliability: Constructed with high-quality, industrial-grade components to ensure a long and predictable service life, minimizing total cost of ownership.

-

Access to Technical Support: Sourcing genuine parts ensures access to official ABB technical documentation, firmware updates, and expert support.

-

Warranty and Traceability: Genuine parts come with a warranty and full traceability to the original manufacturer, protecting against the risks of counterfeit components.

Frequently Asked Questions (FAQ)

Q1: What is the difference between the KUC755AE105 and the KUC755AE106?

A1: The difference typically lies in the specific firmware, processing speed, or memory configuration tailored for slightly different application requirements or product revisions. Both are part of the same family, but the 3BHB005243R0105 article number must be used for the exact KUC755AE105 specification.

Q2: Can this module be used for safety instrumented systems (SIS)?

A2: Yes, the KUC755AE105, particularly when configured in a TMR architecture, is often used as a Logic Solver in Safety Instrumented Systems (SIS) for turbine protection, meeting high Safety Integrity Level (SIL) requirements.

Q3: What engineering tool is used to program the KUC755AE105?

A3: It is programmed and configured using ABB's Control Builder M engineering tool, which is part of the Symphony Plus suite.

Q4: Do you offer technical support for integrating this module?

A4: We supply the guaranteed genuine hardware module. For complex system integration and programming services, we recommend working with a certified ABB system integrator or ABB's own service organization.

Call to Action

Do not compromise the safety and efficiency of your critical turbine assets. Secure your operations with the industry-proven ABB KUC755AE105 controller.

Contact us today for a competitive quotation, detailed datasheets, and current stock availability. Our technical sales team is ready to assist you in sourcing the correct component for your application.

ABB KUC755AE105, 3BHB005243R0105, KUC755 AE105, KUC755AE105 3BHB005243R0105, Turbine Control Module, ABB Symphony Plus, TMR Controller, Triple Modular Redundant, Turbine Governor, Harmony Innovation Controller, Gas Turbine Control, Steam Turbine Control, Compressor Control, S800 I/O, Critical Control System, ABB Spare Parts, 3BHB005243R0105 KUC755AE105.

Sweden

Sweden

.jpg)