In the complex ecosystem of industrial automation, the reliability of your control system hinges on the performance of its core components. The ABB S-073N, with the specific article number 3BHB009884R0021, is a critical module within ABB's renowned industrial I/O system. Whether you are a control engineer tasked with system integration, a maintenance technician troubleshooting a fault, or a procurement specialist sourcing a replacement, having a single, authoritative source of information is paramount.

This guide is designed to be exactly that—your definitive digital manual for the S-073N module. We will delve into its technical specifications, functional role, typical applications, and provide direct access to essential documentation. Our goal is to empower you with the knowledge needed to integrate, maintain, and procure this component with confidence.

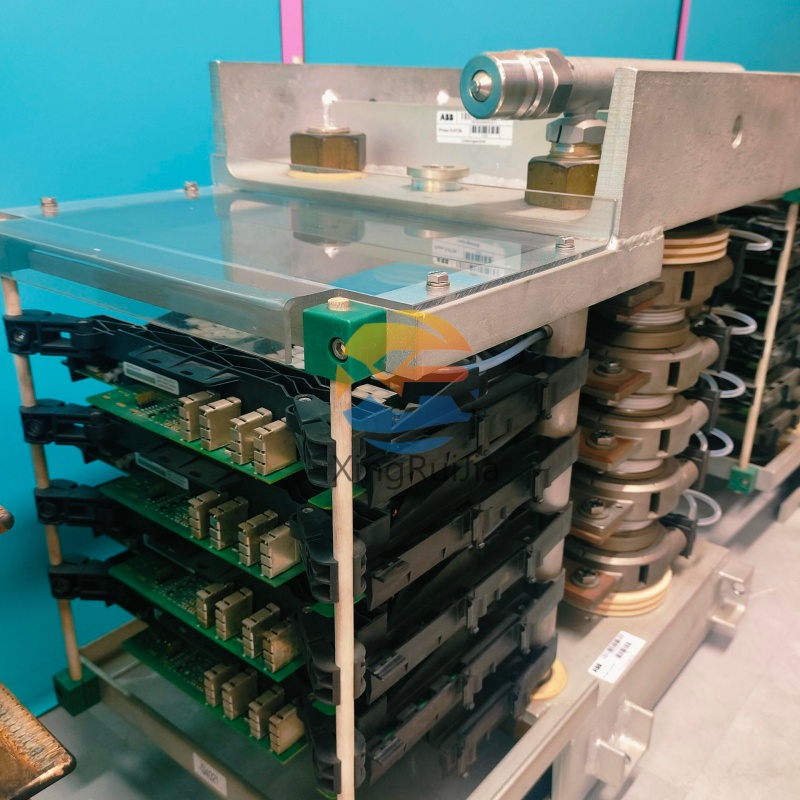

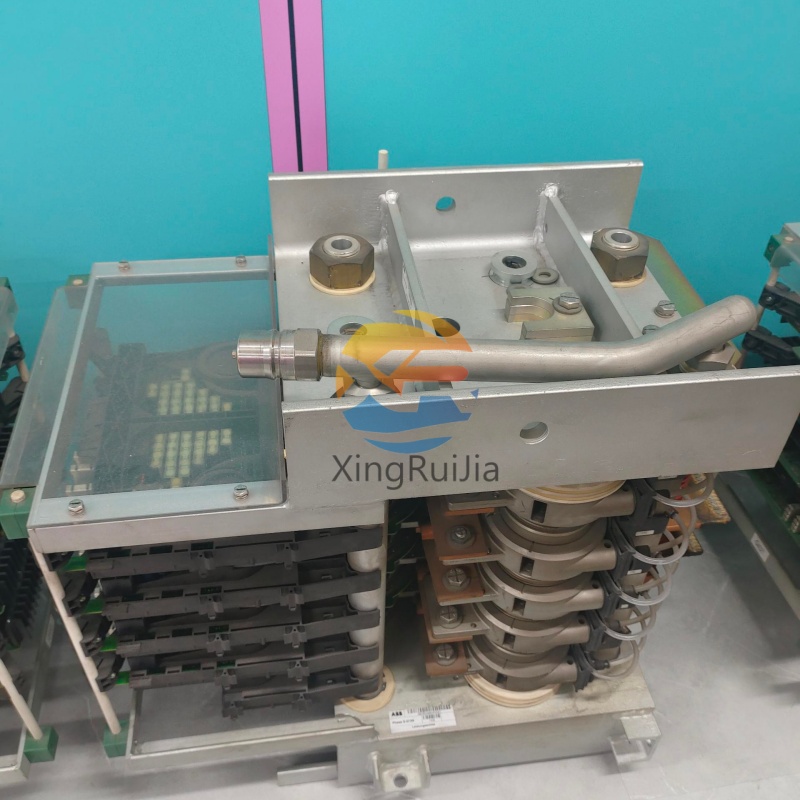

The ABB S-073N 3BHB009884R0021 is a high-performance, digital or analog I/O (Input/Output) module, typically part of ABB's Advant or AC 800M controller families. It acts as the crucial interface between the central processing unit (CPU) of the PLC/DCS and the physical devices in the field.

In simple terms, its job is to:

Receive signals from sensors and switches (e.g., a valve position limit switch, a pressure transducer) and convert them into digital data for the CPU to process.

Send commands from the CPU to actuators in the field (e.g., turning a motor on/off via a contactor, positioning a control valve).

This specific module is designed for high-density I/O applications, allowing a large number of field devices to be connected to a single controller, thereby optimizing cabinet space and system cost.

Precision is key in industrial automation. Below is a comprehensive table of the technical specifications for the S-073N module. This data is essential for system design, compatibility checks, and replacement procedures.

| Feature | Specification |

|---|---|

| Manufacturer | ABB (Asea Brown Boveri) |

| Article Number | 3BHB009884R0021 |

| Module Type | S-073N (Typically a Digital or Analog I/O Module) |

| Product Line | Advant Controller Series / AC 800M |

| I/O Type | High-Density Digital Input/Output (DI/DO) or Analog Input (AI) |

| Voltage Rating | 24 VDC (Standard for industrial control systems) |

| Number of Channels | 16 or 32 channels (configurable in groups) |

| Isolation | Optical or Transformer-based isolation for noise immunity and safety |

| Backplane Communication | Proprietary ABB Fieldbus (e.g., AF 100) |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -40°C to +70°C (-40°F to +158°F) |

| Relative Humidity | 5% to 95% (non-condensing) |

| Safety Standards | Complies with IEC, UL, cUL, and CE standards |

Important Note: The exact channel count and type (sinking/sourcing for digital, voltage/current for analog) can have variants. Always cross-reference the markings on the module's label and use the official datasheet for final confirmation.

The S-073N module is deployed across various industries due to its reliability and flexibility. Its primary role is to consolidate a large number of I/O points efficiently.

Automated Assembly Lines: Monitoring presence sensors, reading barcode scanners, and controlling robotic tool changers.

Packaging Machinery: Managing photoelectric sensors for product detection, controlling solenoid valves for pneumatic actuators, and receiving signals from encoders.

Chemical and Pharmaceutical Plants: Interfacing with level transmitters, pressure sensors, and temperature probes in batch processes.

Water and Wastewater Treatment: Monitoring pump statuses, valve feedback, and flow meter outputs across a treatment plant.

Substation Automation: Acquiring statuses of circuit breakers and disconnectors and monitoring auxiliary contacts.

Power Plant Auxiliary Systems: Controlling and monitoring fans, pumps, and heaters on the plant floor.

Proper installation is critical for long-term reliability. Incorrect wiring is a leading cause of module failure.

Power Down: Always de-energize the controller and the field power supplies before installation or wiring.

Grounding: Ensure proper grounding of the module's chassis and the communication backplane to prevent electrical noise and potential damage.

Connector Use: The S-073N typically uses a removable terminal block connector. Carefully insert the wires according to the pinout diagram.

Wire Labeling: Meticulously label all wires at both ends. This is invaluable for future troubleshooting and modifications.

Fusing: Protect field wiring and the module's internal circuits with appropriately rated fuses or circuit breakers.

The module is equipped with LED indicators that provide real-time status information:

PWR (Power): Green LED indicates the module is receiving power.

RUN / OK: Green LED blinking or steady indicates normal communication with the CPU.

I/O Status LEDs: Individual LEDs for each channel or group of channels show the real-time state (ON/OFF for digital, active for analog).

ERR / FAULT: A red LED illuminates if a hardware fault, configuration error, or communication loss is detected.

A systematic approach is key to resolving issues with the S-073N module.

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| No LED Indicators Lit | No power to the module or backplane. | Check system power supply and fuses. Verify the module is fully seated in its slot. |

| 'ERR' / 'FAULT' LED Lit | Module hardware failure. Configuration mismatch. | 1. Cycle power. 2. Reseat the module. 3. Check the controller's configuration against the physical hardware. 4. Replace the module if the error persists. |

| Specific Channel Not Working | Faulty field device. Broken wiring. Fuse blown. | 1. Use a multimeter to check for the field signal at the terminal. 2. Check the field device (e.g., sensor, actuator). 3. Inspect and replace the channel fuse if applicable. |

| Module Not Recognized by CPU | Wrong slot address. Faulty backplane. Firmware issue. | 1. Verify the module's slot address in the hardware configuration software. 2. Try the module in a different, known-good slot. 3. Check for and update module firmware. |